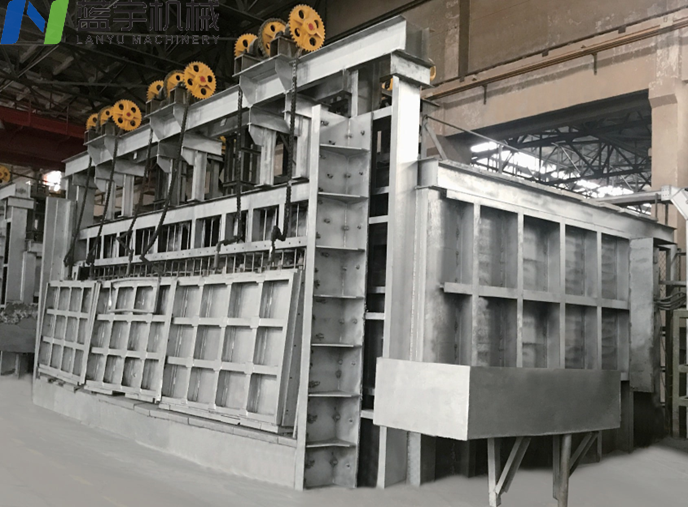

Electrolytic aluminum smelting holding furnace

- Smelting furnace , Holding furnace

- April 26, 2025

Table of Contents

Main Applications

This melting furnace is specifically designed for aluminum electrolysis plants, primarily used for heat preservation and casting processes of high-temperature aluminum liquid. The equipment not only efficiently maintains the temperature of molten aluminum to ensure product quality stability but also directly performs alloying treatments, producing high-value-added products such as aluminum alloy ingots and aluminum alloy rods. This solution optimizes production processes, improves efficiency, reduces energy consumption, and creates greater economic benefits for enterprises.

Technical Specifications

Structure of the Melting Furnace

- Steel frame furnace body

- Insulation materials

- Refractory lining material

- Furnace roof design

- Lifting furnace door

- Hoisting mechanism

- Combustion system

Selectable Structures of the Melting Furnace

Types of Furnace Body

- Double-channel steel composite furnace body

- I-beam furnace body

Furnace Roof Design

- Suspended brick castable roof

- Castable arch roof

Melt Pool Structure

- Melt pool brick masonry structure

- Semi-cast structure

- Full cast structure

Heating Methods and Energy Types

- Silicon carbide rod heating

- Natural gas

- Heavy oil

- Diesel

- Biodiesel

- Coal and coal gas

The construction costs, service life, and effects of different structures vary; the optimal solution can be chosen based on specific requirements.

Main Models

25T, 30T, 35T, 40T, 45T, 50T, 60T