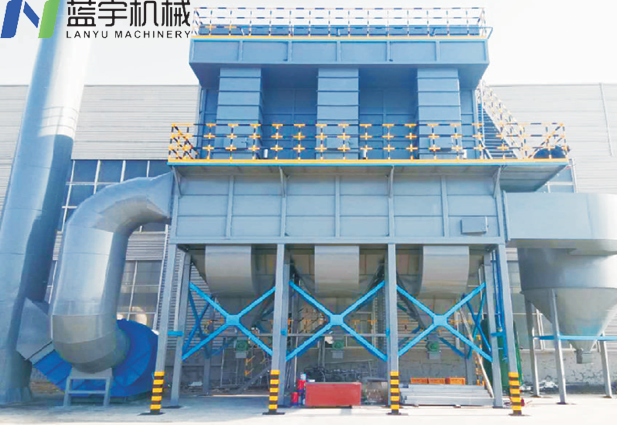

Pulse Bag Dust Filter

- Filter & degassing

- April 26, 2025

Table of Contents

Main Applications >

This equipment is primarily used for dust collection and fume treatment in industries such as non-ferrous metal smelting, recycling of scrap metal, ceramics, and cement production. Its highly functional design effectively captures and removes dust and harmful gases generated during the production process, ensuring a clean and compliant working environment. It is suitable for enterprises of various scales, helping to achieve important goals of environmental protection and improved production efficiency.

Product Specifications >

Dust removal efficiency ≥ 99.5%;

Particulate emission concentration ≤ 10 mg; Ringelmann blackness: 1 degree.

Technical Features >

Indoor Shutdown Pulse Lock Cleaning Technology

- Overcomes the shortcomings of traditional pulse dust collectors and indoor reverse blow dust collectors.

- Strong cleaning ability, high dust removal efficiency, low emission concentration.

- Low leakage rate, energy saving, small footprint, stable and reliable operation, good economic benefits.

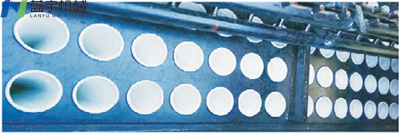

Maintenance and Bag Replacement

- No need to shut down the system fan; maintenance is performed under normal operating conditions in individual rooms.

- The bag mouth uses an elastic expansion ring for good sealing performance, ensuring reliability.

- The bag cage adopts a multi-angled design, reducing friction between the bag and cage, extending service life, and facilitating bag removal.

Bag Replacement Method

- Uses an upper extraction method; after removing the frame, dirty bags can be directly placed into the lower ash hopper of the housing and removed through the access port.

- Improves traditional dust collector bag replacement operation conditions, enhancing maintenance convenience.

Automatic Airflow Control Setting

- The system design supports automatic airflow adjustment functionality.

Housing Airtightness Design

- Excellent sealing performance; inspection doors use high-quality sealing materials.

- Tested for leaks with coal oil during production to ensure low leakage rate.

Filter Material Selection

- Selected based on working conditions such as dust-laden gas temperature, moisture content, acidity or alkalinity, dust viscosity, concentration, and particle size to meet different requirements.

Control System

- Bag-type pulse dust collector cleaning uses PLC microcomputer program control.

- Supports three control modes: automatic pressure (auto), automatic timing, and manual.