Stacking Robot

- Stacking robot

- April 26, 2025

Table of Contents

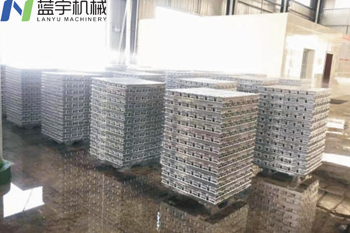

Major Applications >

The Stacking Robot system, as an integrated automated equipment, has been widely applied in various industries such as mechanical manufacturing, food, feed, pharmaceuticals, chemicals, and cement. Our company specializes in developing palletizing robot systems tailored for production lines of non-ferrous metals such as aluminum, zinc, lead, and copper ingots. This system achieves automatic handling and efficient palletizing of aluminum ingots. Not only does this equipment significantly reduce labor costs but also greatly enhances production efficiency. Additionally, it optimizes workshop layouts, reduces floor space requirements, and effectively improves the production environment. Through our automation solutions, we are committed to helping customers build intelligent and efficient non-ferrous metal production processes, thereby enhancing enterprise competitiveness and operational efficiency.

Product Features >

Operational Performance

- Stable Operation: The system is meticulously designed to ensure long-term stable operation with minimal maintenance requirements.

- High Palletizing Precision: Utilizes advanced servo motor-driven technology for precise palletizing operations.

Ease of Use

- Simple Operation: User-friendly interface design with one-button start functionality, reducing operational complexity.

Technical Advantages

- Low Noise and Failure Rate: Servo motor-driven operation ensures quiet running and high reliability, minimizing equipment failures.

Production Efficiency

- High Work Efficiency: A single unit can replace 3-5 workers, significantly improving work efficiency.

- Multi-threaded Support: Supports simultaneous palletizing of ingots across multiple production lines, greatly reducing production costs.

Space and Installation

- Compact Design: Compact equipment design saves workshop space.

- Flexible Installation: Customized installation and deployment can be tailored to the actual site conditions of customers.

Environmental Adaptability

- Strong Adaptability to Harsh Environments: Stable operation in relatively demanding working environments, meeting diverse production needs.

Performance Specifications >

- Gripper Effective Size: 760 x 780 MM

- Rotation Speed per Cycle: 3.5 - 5 Seconds

- Maximum Palletizing Height: 1680 MM

- Robot Arm Rotation Angle: 360 Degrees (Freely Settable)

- Working Range: R ≥ 1500 MM

- Maximum Load Capacity: 220 KG