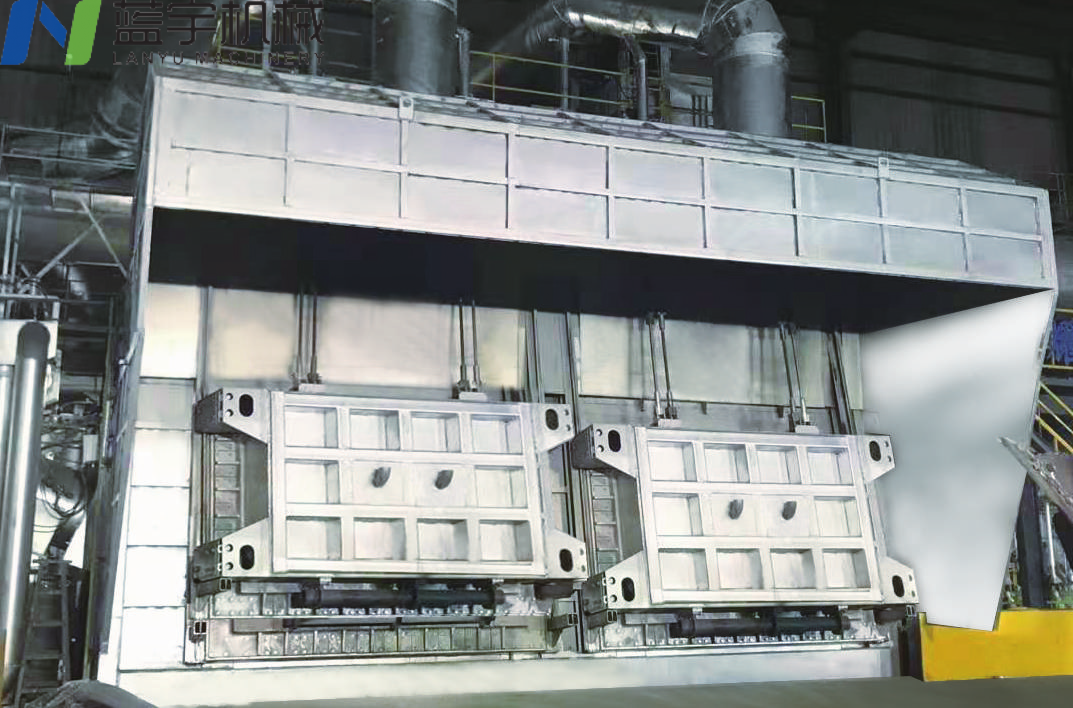

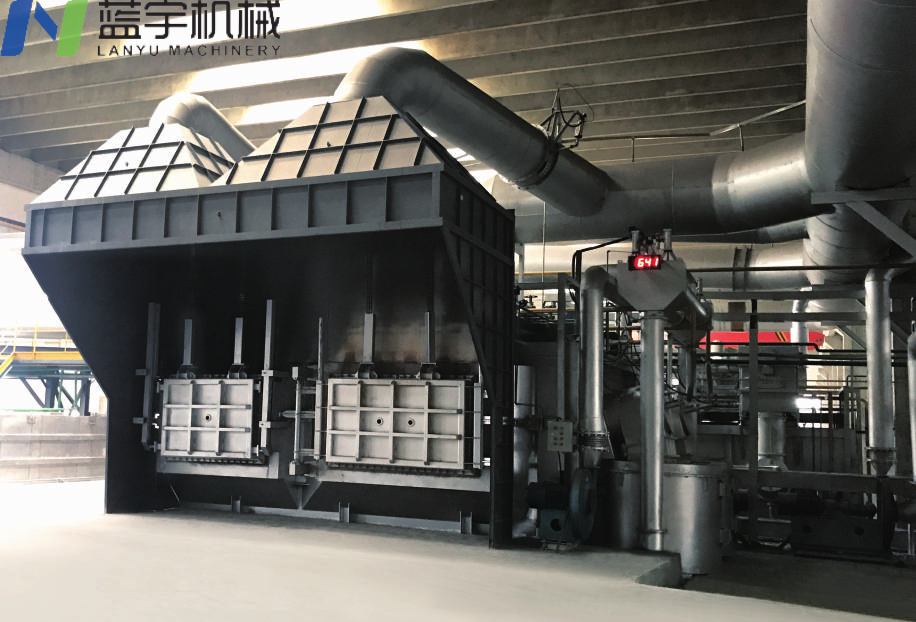

Double Chamber Side Well Melting Furnace

- Smelting furnace

- April 26, 2025

Table of Contents

Primary Applications >

The Double Chamber Side Well Melting Furnace is specifically designed for the high-temperature melting of aluminum fluff, soda cans, radiator aluminum, and thin aluminum materials. It is particularly suitable for recycling aluminum production and remelting of scrap aluminum. The unique double-chamber structure ensures efficient melting of aluminum materials in a fire-free high-temperature aluminum environment, significantly reducing material loss. Compared to traditional furnace designs, the recovery rate is improved by 2%-3% or more. This equipment can process 3-10 tons of aluminum fluff or soda cans per hour, offering performance comparable to Parikh aluminum liquid pumps but with a better cost-performance ratio, making it an ideal choice.

Technical Specifications >

Basic Components

- Furnace Body: Constructed using structural steel (double I-beam or I-shaped steel), ensuring high strength and stability.

- Insulation and Lining: Utilizes high-quality insulation and refractory materials to ensure efficient heat retention and long service life.

- Partition Walls and Roof: Partition walls to minimize heat loss, with roof options including hanging bricks, castable arches, or masonry structures to meet different requirements.

- Double-Rising Door Mechanism and Lifting Devices: Optimizes the operating process for enhanced safety and efficiency.

- Melting System: Includes side wells, aluminum liquid pumps, charging systems, and combustion systems for efficient melting.

Structural Design Variability

- Furnace Types:

- Double I-beam furnace body provides greater load capacity, while I-shaped steel furnace body offers a more economical solution.

- Roof Design: Options include hanging brick arches, castable arches, or masonry arches to satisfy diverse insulation and structural needs.

- Melt Pool Structure: Available in masonry, semi-castable, or fully castable configurations, affecting service life and maintenance costs.

Flexible Heating Energy Selection

- Supports multiple fuel types: natural gas, heavy oil, diesel, bio-oil, coal, and coke oven gas, adapting to regional energy supplies and environmental standards.

Diverse Design Configurations

- Single Furnace (Primary Furnace): Suitable for small-scale production or simple process flows, offering ease of operation.

- Mother-Son Furnace (Secondary Furnace): Features a two-tier design with a high炉and low furnace configuration to enhance melting efficiency and output, ideal for continuous production demands.

Major Models >

15T, 20T, 25T, 30T, 35T, 40T, 45T, 50T, 60T, 70T, 80T, 100T, 120T