Product List

- Home /

- Product List

Energy Eficient Regenerative Combustion System

Application Scope > The Energy Eficient Regenerative Combustion System has extensive applicability and can be used with various non-ferrous metal melting furnaces,保温 furnaces, and heating furnaces. This system is primarily used for the pre-melting process of aluminum alloy ingots, zinc alloy ingots, aluminum alloy rods, aluminum plates/bands, aluminum wheels, and zinc-aluminum die-cast products. It is currently the most efficient, energy-saving, and environmentally friendly ideal choice.

Read More

Low Nitrogen Diffusion Combustion System

Application Scope The Low Nitrogen Diffusion Combustion System is suitable for various non-ferrous metal melting furnaces and holding furnaces, widely used in the initial melting and heat preservation processes of products such as aluminum alloy ingots, zinc alloy ingots, aluminum alloy bars, aluminum plates/aluminum strips, aluminum wheels, and zinc-aluminum die-castings. As an efficient, energy-saving, and environmentally friendly product, this system meets modern manufacturing demands for energy optimization and environmental protection, making it an ideal choice to enhance production efficiency and reduce operational costs.

Read More

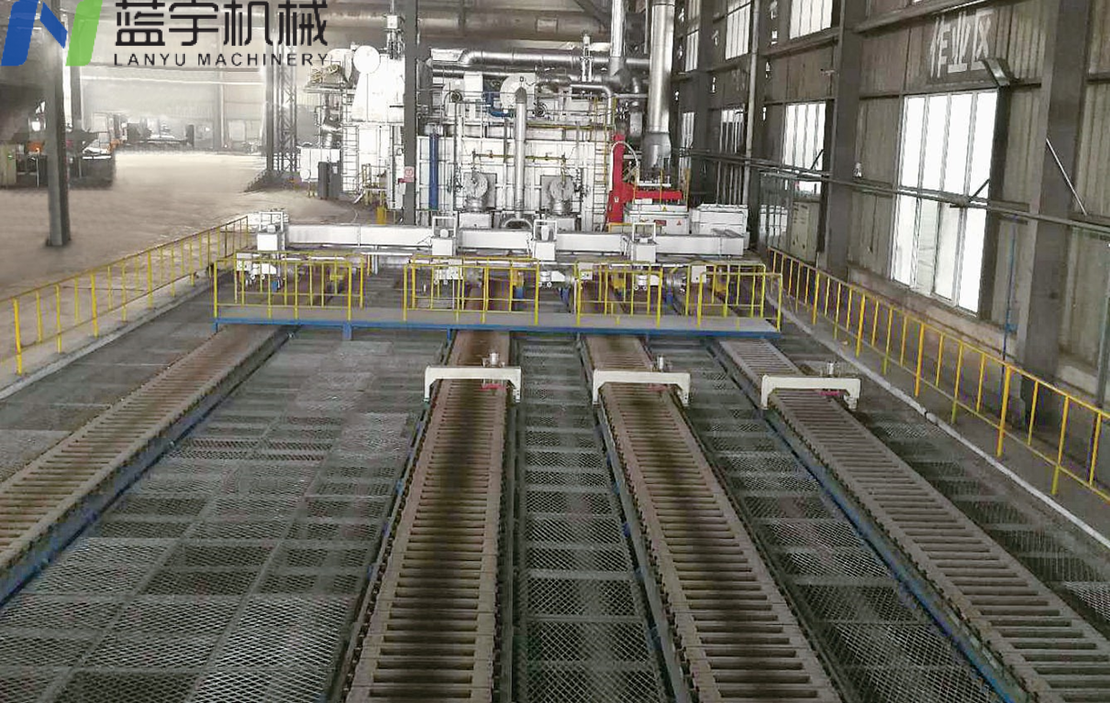

Alloy Ingot Casting Machine

## Main Applications The ingot casting machine is a key device in the metallurgical industry used for forming ingots. It is widely applied in the production of aluminum ingots, zinc ingots, lead ingots, copper ingots, aluminum alloy ingots, zinc alloy ingots, and other metal materials. This equipment employs advanced variable frequency speed regulation technology, significantly improving production efficiency. Its straight-line design ensures uniformity of ingot blocks while effectively reducing manual labor intensity. The machine has a maximum width of 1.5 meters and a length typically ranging from 18 to 25 meters, meeting the needs of different scales and types of casting processes.

Read More

Stacking Robot

Major Applications > The Stacking Robot system, as an integrated automated equipment, has been widely applied in various industries such as mechanical manufacturing, food, feed, pharmaceuticals, chemicals, and cement. Our company specializes in developing palletizing robot systems tailored for production lines of non-ferrous metals such as aluminum, zinc, lead, and copper ingots. This system achieves automatic handling and efficient palletizing of aluminum ingots. Not only does this equipment significantly reduce labor costs but also greatly enhances production efficiency. Additionally, it optimizes workshop layouts, reduces floor space requirements, and effectively improves the production environment. Through our automation solutions, we are committed to helping customers build intelligent and efficient non-ferrous metal production processes, thereby enhancing enterprise competitiveness and operational efficiency.

Read More

Rotary Furnace

Overview > The rotary furnace, as an important equipment for the melting furnace, is mainly used in the thermal slag recycling stage of aluminum scrap processing. It plays a key role in improving the aluminum recovery rate. This equipment consists of a machine frame, a rotary cylinder, and a lifting system, with three specifications: 3T, 5T, and 8T. Users can choose according to their actual processing capacity.

Read More

Aluminum Dross Cooling Machine

Overview > The screening-type cold ash drum is a cooling and screening device used in conjunction with rotary furnaces, primarily for processing hot aluminum dross. It utilizes a spray cooling method to rapidly reduce the temperature of aluminum dross from over 700°C to below 50°C, effectively preventing combustion and oxidation. As a critical component in the recycling process of aluminum dross, this equipment plays a significant role in improving aluminum recovery rates. The screening-type cold ash drum consists of components such as water tanks, cooling drums, ball mill drums, screening drums, and control systems. It is available in three series based on drum diameter: 1200-type, 1600-type, and 1900-type. Each series offers five additional specifications based on length: 8 meters, 11 meters, 13 meters, 15 meters, and 17 meters.

Read More