Product List

- Home /

- Product List

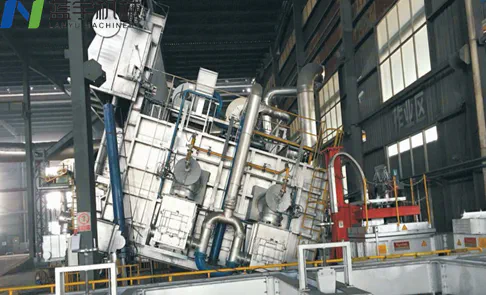

Double Chamber Side Well Melting Furnace

Primary Applications > The Double Chamber Side Well Melting Furnace is specifically designed for the high-temperature melting of aluminum fluff, soda cans, radiator aluminum, and thin aluminum materials. It is particularly suitable for recycling aluminum production and remelting of scrap aluminum. The unique double-chamber structure ensures efficient melting of aluminum materials in a fire-free high-temperature aluminum environment, significantly reducing material loss. Compared to traditional furnace designs, the recovery rate is improved by 2%-3% or more. This equipment can process 3-10 tons of aluminum fluff or soda cans per hour, offering performance comparable to Parikh aluminum liquid pumps but with a better cost-performance ratio, making it an ideal choice.

Read More

Rectangular Smelting Furnace Group / Holding furnace

Primary Applications > The rectangular melting furnace is primarily used for high-temperature melting of solid aluminum and alloy ingots, with functions to maintain the temperature of molten aluminum. It also effectively handles the melting of difficult-to-melt alloys. This equipment is particularly suitable for the melting and refining processes of recycled aluminum. In addition, this advanced, energy-efficient, and environmentally friendly device excels in the initial melting stage required for producing high-quality aluminum alloy ingots, aluminum alloy rods, aluminum plates, aluminum strips, aluminum wheels, and aluminum die-cast products. It not only meets the needs of aluminum alloy melting but can also be extended to melting processes for other non-ferrous metals such as copper, zinc, and lead.

Read More

Circular Smelting Furnace Group / Holding furnace

Main Applications The circular melting furnace is primarily used for the high-temperature melting process of solid aluminum and aluminum alloy ingots. It is widely applied in the melting and refining processes of recycled aluminum and is particularly suitable for the initial melting stage in the production of high-quality aluminum alloy ingots, bars, sheets, rims, and castings. This equipment is highly efficient, energy-saving, and environmentally friendly. Additionally, it can be used for the melting process of other non-ferrous metals such as copper, zinc, and lead. Its design focuses on performance optimization, energy efficiency, and environmental protection requirements, providing an ideal solution for the metal processing industry.

Read More

Electrolytic aluminum smelting holding furnace

Main Applications This melting furnace is specifically designed for aluminum electrolysis plants, primarily used for heat preservation and casting processes of high-temperature aluminum liquid. The equipment not only efficiently maintains the temperature of molten aluminum to ensure product quality stability but also directly performs alloying treatments, producing high-value-added products such as aluminum alloy ingots and aluminum alloy rods. This solution optimizes production processes, improves efficiency, reduces energy consumption, and creates greater economic benefits for enterprises.

Read More

Tilting Smelting Furnace / Holding furnace

Main Applications > The inclined pouring melting furnace and insulation furnace are primarily used in enterprises producing high-end aluminum alloy rod materials and aluminum sheet/band products. By precisely controlling the casting process of molten aluminum, it is possible to effectively improve product quality and production efficiency while reducing safety risks and preventing explosion accidents. This equipment is particularly suitable for enterprises engaged in recycled aluminum processing and scrap aluminum remelting.

Read More

High Efficiency Preheating Kiln for scrap Aluminum

Overview The High Efficiency Preheating Kiln for scrap Aluminum is a new type of equipment developed based on the drum dryer. It is primarily designed to address the treatment of oil and moisture in waste aluminum, aluminum shavings before smelting, and to achieve effective preheating of materials. The equipment dries materials containing certain metallic substances (such as silicon carbide powder, iron shavings, raw iron shavings, iron powder, aluminum shavings, cans, raw and sintered aluminum, copper powder, steel shavings, ores, etc.) to a dry state before smelting, thereby achieving the goal of refining pure aluminum while effectively reducing energy consumption. This equipment is particularly suitable for drying large-particle, high-density materials in industries such as metallurgy, mining, and chemicals. The heat source can be flexibly selected based on requirements, using various fuels or utilizing industrial furnace flue gas to provide efficient thermal solutions tailored to different application scenarios.

Read More